Phone Number

+91-9879091953

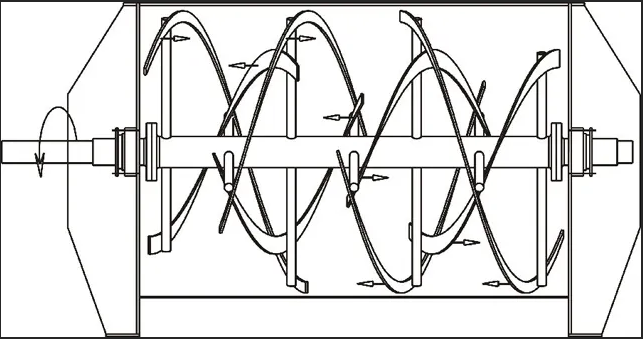

Ribbon Blender comprises of a U-shaped horizontal trough and a specially designed Double Helical Ribbon Agitator rotating within. Ribbon Blenders are based on a proven agitator construction that provides a triple mixing action ensuring fast, efficient blending. The dimensions and configuration of the ribbons are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge.

An alternate design is the paddle agitator Blender. The paddles are positioned to move the material in opposing lateral directions as well as radially. The paddle design is generally employed where friable materials are being blended, and when batches as small as 15% of the total capacity are going to be mixed in the blender.

Ribbon type Blenders are uses in wide range of industrial applications in pharmaceutical, cosmetic, chemical, food, nutraceutical, herbal, agriculture and allied industry. The ribbon mixer's flexibility for blending powders with its ability to perform heating, cooling, coating, and other processes make it very popular blender. The following are the major applications of the Ribbon Blender:

Pharmaceuticals Application: Bulk Drugs, API and Nutraceuticals

Cosmetics Application: Talcum Powder, Eye shadow, Face powders, Laundry detergents

Chemicals Application: Dyes, Intermediates, Pigments, Pesticides, Fine Chemicals, Rubber Chemicals, Abrasives, Engineered plastic resins, Epoxy resins, Carbon black, Fire retardants, Polyethylene, Chemicals, Gypsum, PVC compounding, Cleaning compounds, Plastic powders

Food Appliactions: Infant formula, Cocoa mix, Instant salad dressing, Cake mixes, Seasonings, Flavorings, Gelatin, Milk Powder, Pet foods, Bakery premixes, Cake mixes, Instant breakfast cereals, Spice blends, Dietary supplements, Instant drink blends, Spices, Dried food products

Agrculture Application: Insecticides, Pesticides, Fertilizers, Pesticides and herbicides, Bird seeds

Other Applications: Handling large Dry and wet powder volume, Crystalline products, Low-viscosity paste and liquid in chemicals

Material is charged in the blender through nozzles or feed-hoppers mounted on the top cover of the blender. Suppose if screw feeder is opted with mixer then material to be load onto screw feeder and it will feed powder into blender. Filling to be done about 70 percent of the total volume of the container. This is generally up to the level of the outer ribbon's tip. After feeding completes then please close the top cover of the blender and tighten the latches. Now start the machine form the control panel.

During the blending operation in Granular Horizontal Ribbon Blender/Powder Mixer manufacture, the outer ribbons of the agitator interchange the material from the ends to the center while the inner ribbons transfer the material from the center to ends. Radial movement is achieved because of the rotational motion of the ribbons. The difference in the peripheral speeds of the outer and inner ribbons results in axial movement of the material along the horizontal axis of the blender. As a result of the radial and the counter-current axial movement, homogenous blending is achieved in short time. Blending is generally performed in 15 to 20 minutes cycle time. Mixing efficiency of ribbon blender depends upon particle size and its bulk density. Generally ribbon mixer blender with 95% efficiency in most of the cases. Ingredients with similar particle size and bulk densities tend to mix faster as compared to ingredients with variation in these attributes.

After mixing, material is discharged from a discharge valve located at center bottom of container. The discharge can be fitted with any of these valves like slide-gate, butterfly, flush bottom, spherical and other types depending on the application. The operation of the valves can be manual or pneumatically actuated as per requirements. Sifter can be installed at discharge of the blender for sieving the output materials. Ribbon blenders can be designed for multiple discharge ports. Unlike tumbling blenders where 100% discharge of material is achieved by gravity, in a ribbon blender the material is discharged by rotation of the ribbon agitator. Finished powder can be collected directly on mobile container or can discharge onto conveyor for further operations.

| Model | Gross Volume approx. | Working Volume approx. | Power |

| RM-10 | 10 Liters | 5 Liters | 0.5 H.P. |

| RM-50 | 50 Liters | 20 Liters | 1 H.P. |

| RM-75 | 75 Liters | 50 Liters | 1 H.P. |

| RM-150 | 150 Liters | 100 Liters | 2 H.P. |

| RM-250 | 250 Liters | 150 Liters | 3 H.P. |

| RM-450 | 450 Liters | 300 Liters | 5 H.P. |

| RM-600 | 600 Liters | 450 Liters | 7.5 H.P. |

| RM-1100 | 1100 Liters | 750 Liters | 10 H.P. |

| RM-1500 | 1500 Liters | 1000 Liters | 12.5 H.P. |

| RM-2000 | 2000 Liters | 1250 Liters | 15 H.P. |

| RM-3000 | 3000 Liters | 1875 Liters | 20 H.P. |

| RM-5000 | 5000 Liters | 3000 Liters | 25 H.P. |

| RM-10000 | 10000 Liters | 6000 Liters | 40 H.P. |

* Power voltage can be adjusted as per customer's domestic power voltage requirements.

* Rights of technical improvements & modification reserved.

* Illustrations & dimensions are shown for information purpose only.